Manufacturing and supply chain is experiencing a tectonic shift in operations. It is a thrilling time to be in the industry, as most businesses have keen interest to integrate automation and seek the practicality of robotic integration into production. If businesses do not adapt and meet the customers’ insatiable need for increases in delivery speed, you can be sure the competition will. RIOS Intelligent Machines is rising to meet customer demands as businesses line up for robotic solutions to transform their operations, leverage human workforce, streamline processes, and reduce tedious, manual operations.

The Time is Now to Invest in Automation

The obvious pains that exist in today’s business climate include shortage of labor, supply chain pressures, increased speed to meet customer demand. Generally, businesses that invest in automation increase operational efficiency, increase production speed, and reduce labor pains. With automation, businesses have more opportunity to shift valuable human capital to other functions around the facility. Robotic automation is gaining in sophistication and availability and now can handle more diverse and complex functions as robotic technologies transform traditional manufacturing and improve profitability.

Why AI / Full Stack Solutions

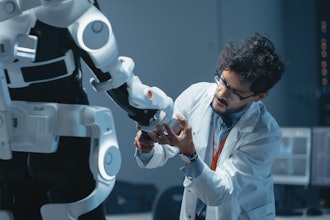

Tasks in a warehouse, while seemingly easy, are highly variable and require thought processes, sensing, and the dexterity of humans. A full stack robotics solution can achieve these goals as a robot needs vision, artificial intelligence, and the ability to grasp to adapt to real world situations within a facility. What does a robot need to perform the same? Robotic work cells are in facilities completing work previously done by human operators, saving in operating costs, and providing frictionless service.

Robotic integration is highly impactful to operations, can be easy to integrate, as well as provide meaningful data to enhance future operations. New robotic equipment seamlessly integrates into existing infrastructure and simply installs into place.

Businesses Need Speed

Now, more than ever, operational success is benchmarked upon speed. Customer decisions are based on the speed of product delivery and instant gratification. It is increasingly cumbersome to deliver complex product solutions to customers as rapidly as humanly possible. Yet becoming faster is a critical competitive advantage for production. Through the integration of automation and robotic solutions, customers are discovering endless applications for process improvements to reap the benefits of robotic automation.

RIOS-built Robots

RIOS builds the full stack of dexterous, AI-powered robots embedded with human-like capabilities that can easily handle increasingly complex manipulation tasks. RIOS uses an approach based on developing a central AI platform (brain), AI-driven perception system (eye), and haptic intelligence (touch). RIOS best-in-class robots and its level of performance is unlike anything that the world has seen so far, as it is much more than specializing in singular componentry. The advanced AI platform is responsible for vision perception, tactile perception, and real-time motion planning and control of the robot. Like the brain of a child, the platform constructs models of the world and evolves with new experiences -- allowing the robot to be rapidly reconfigured to perform different tasks. RIOS customers' machine performance continuously improves over time, providing continuous value to the organization.

Robots have to sense the fragility of an object. These robots know the perfect amount of pressure to place on an object to safely transport it from inbound to outbound location without too much pressure that would damage an object, or not enough pressure that would result in a dropped item. After all, it’s of utmost importance that not only an item makes it to the packing box, but it must also be damage free for customer satisfaction. Currently, this is only something that a person is capable of, and RIOS has solved this.

Why I Joined RIOS

I have seen many operational challenges first-hand in many manufacturing and supply chain facilities. Robotics and automation are leading the future and there is unbeatable energy in the manufacturing space. Ultimately, robotic solutions, such as RIOS robotic work cells, will be one of the primary equipment integrations which will propel customers’ operations into the future.

Kelly Kamlager is Sr. Director of Marketing for RIOS Corporation. For more information, visit www.rios.ai.