OPEN MIND Technologies AG (Needham, MA) a leading developer of CAD/CAM software solutions worldwide, has introduced its latest hyperMILL 2022.1 CAD/CAM software suite which offers users new and enhanced features for even more powerful NC programming in applications ranging from 2.5D to 5-axis.

The company will demonstrate the new capabilities at IMTS (Booth 133351) in the Controls and CAD/CAM Pavilion, East Hall in McCormick Place, Chicago, from Sept. 12-17th.

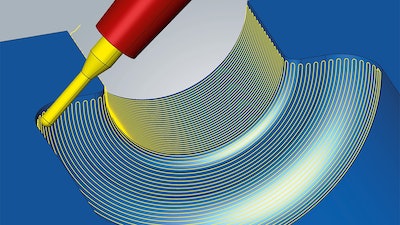

Highlights in hyperMILL 2022.1 include a new break-edge function for contour milling, combined pocket milling together with a finish path allowing cutter compensation, and increased efficiency for 3D plane machining. The new automated 3D plane machining strategy improves machining quality by searching for suitable, high performance path layouts according to parameters including when adaptive pockets are present.

For improved tool data reliability and time savings, tool data such as length, radius, corner radius, and tool number and name, can be transferred directly from hyperMILL to a Heidenhain TNC640 control using the hyperMILL CONNECTED Machining module. Now it is possible to import calibrated tools from a tool management system into hyperMILL to create programs, and then transfer the tool list or individual tool data to the machine.