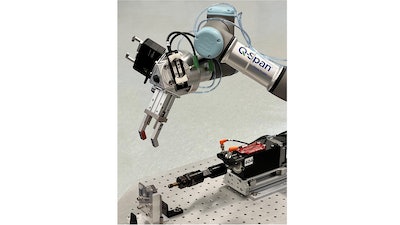

The Q-Span Workstation incorporates existing manual gauges, such as this thread gauge, to automate part handling, gauging and data collection for quality control (QC) teams in high-mix, small-batch manufacturing.

New Scale Robotics

New Scale Robotics (Victor, NY) announced thread verification as the latest enhancement to its Q-Span Automated Gauging System, a do-it-yourself (DIY) robotic automation system for quality teams in high-mix, small-batch manufacturing.

The Q-Span Gauging System features:

- Automates gauging processes

- Combines existing manual gauges with a collaborative robot, grippers, metrology and robot control software and automated data collection

- Robot arm that loads parts into fixture and activates the thread gauge to verify or chase threaded holes or external threads

- Sorts parts based on measured data

- Configurable systems for “GO” gaging, “NO GO” gaging, combination gaging and thread chasing

Data from all gauges, including thread gauges, robotic calipers, LVDT probes, drop gauges, bore gauges, laser micrometers, vision system, 2D telecentric profilers and more, in the Q-Span System is combined into one output for statistical process control (SPC). Data from any or all gauges can be used in real time for in-process decision making and process monitoring.