PixelPaint robotic non-overspray technology for the automotive industry has won this year’s Innovation and Entrepreneurship in Robotics & Automation (IERA) Award for Outstanding Achievements in Commercializing Innovative Robot and Automation Technology.

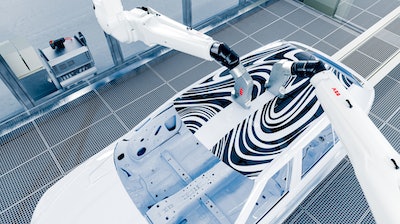

Launched in 2020 by ABB (Cary, NC), PixelPaint uses inkjet head technology to directly apply high resolution two-tone or individualized designs to a car body in a single pass, enabling manufacturers to easily meet the rising demand for customized paint jobs while eliminating wasteful overspray.

Traditionally, applying a two-tone or customized design onto bodywork has required a vehicle to be put through a painting line twice, once for the first layer and then, after the areas have been masked, again for the second color. Typically, masking the bodywork has needed around 10 to 20 operators per shift, with two operators also needed to de-mask it after the second color had been applied.

With only 70 to 80 percent of the paint being applied to the bodywork surface when sprayed, wastage levels have been significant, increasing costs through recycling and having to purchase additional paint.

PixelPaint overcomes these issues, providing a faster, highly accurate and more sustainable solution for customized painting. The PixelPaint cell comprises a high DPI inkjet head, two IRB 5500 paint robots, dosing control package, and RobotStudio programming software for two tone and decorative painting applications.