With the rise of Industry 4.0, an increasing number of companies are choosing to add automation to their operations and packaging facilities are no exception to this trend. According to the International Federation of Robotics (IFR), in 2018 global robot installations increased to 422,271 units, worth USD 16.5 billion.

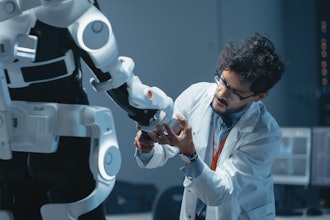

Automation and robotics were first brought to the manufacturing workplace with a view to free workers from dangerous and repetitive tasks, to eliminate human error and to cut costs. Although the adoption of automation has expanded to encompass many industries, this philosophy has not changed.

Most packaging facilities already use some form of automation on site. For example, row-forming palletizers were first introduced in the early 1950s and palletizing robots are now commonplace in most large-scale warehousing facilities. However, new varieties of robotic equipment are revolutionizing the industry, by performing more complicated packaging tasks. So, where do companies start in navigating the expanding pool of automation technologies?

What’s Your Goal?

Firstly, the scale and intricacies of the sites’ separate packaging processes must be carefully considered. For large facilities, plant managers could consider a multi-disciplinary robot that can perform several steps simultaneously, thus streamlining processes for greater efficiency.

Alternatively, they may choose to invest in several different machines to manage separate tasks. It goes without saying, the more automation that is involved, the more complicated the integration process gets.

Whether a packaging company is familiar with automated technologies, or they’re taking the first step into investing in automation, the considerations will often be the same. Plant managers should always consider to what degree they want to automate and how much is necessary for the goal they are trying to achieve.

For example, a warehousing and distribution facility for fast moving consumer goods (FMCG) may have separate packaging areas for both incoming and outgoing goods. At the site, incoming boxes must be opened and unpacked before the materials can be sorted for distribution. To speed up this process, the site could invest in an automated box opening robot — an encased robot that can automatically detect the size of each carton and find the programmed cut lines. This type of robotic machinery removes the need for handheld blades in the warehouse and reduces the chance of cuts and lacerations for human employees.

Despite these benefits, this robot does not offer a complete automation solution. It is only suitable for one small process in the facility and lacks the versatility of six-axis, cartesian or selective-compliance-articulated robot arms (SCARA) robots. Should a plant manager wish to fully automate a site’s packaging process, an investment in several different types of automated equipment is necessary. For instance, on a line that incorporates several processes, a six-axis robot could be used to stack and palletize finished products at the end of the line. Following this, an automated guided vehicle (AGV) might be required to move them to a different area of the factory floor.

For smaller facilities, costly investments in new equipment may not be a viable option. As an alternative, they can look to make small incremental upgrades. Consider this as an example, during the label application process, packaging machines cannot always reliably detect the leading edge of the product, partly due to the increasingly broad range of packaging types. This can lead to the label, bar code or graphics being applied in the incorrect location, thus causing a stoppage in the production line. Adding photoelectric sensors with advanced background suppression could allow the technology to ignore stray background reflections and detect multicolored objects.

Using light triangulation, suppression sensors detect and recognize everything in the sensing area. Plant managers in packaging facilities can use information from these sensors to fine tune leading edge detection in label application, case packing and cartooning, providing a cost-effective alternative to expensive automation. Adding low-cost sensors to a pre-existing machine could collect vital data, relaying information to operators and improving process efficiency and cutting down on material wastage.

Picking Your Processes

Another activity that could benefit from a smaller automation investment is picking and packing processes. To combat bottlenecks that commonly occur at this part of the packaging line, manufacturers can choose an end of arm tooling design (EOAT) on a robot that can pick one or multiple products at a time.

Robotic equipment can be added to front-of-line processes too. Depalletizing, loading, line charging or thermo forming packaging with an injection molding machine are all possible options to improve packaging processes. Similarly, labeling, packing, palletizing and wrapping products — tasks that involve strenuous, laborious manual work — can all be achieved by automated systems.

Adding complicated automation to a packaging process is no easy accomplishment. However, it’s clear that that automation offers many benefits. Whether a facility is large or small, there are options to automate and this certainly cannot be overlooked in the packaging industry. The good news is, EU Automation is here to support you with automation equipment, no matter what stage your business is at in your automation journey.

For more information, visit www.euautomation.com.