The increasing adoption of IoT-based technologies in the industrial segment has generated an increased demand for remote monitoring solutions, interactive display modules and more efficient HMI devices. Since the advent of the COVID-19 pandemic, contactless touch monitors and displays have begun replacing conventional touchscreens in the industrial workplace.

Solutions such as using infrared technology to track finger movements a few centimeters from the surface of the display are the prevailing solution. The advantages of this HMI technology are obvious: it is highly responsive even when the user is wearing work gloves, zero contact means zero germs and less clean-up from greasy build-up on surfaces, and less damage to the display surface from over-enthusiastic interaction.

Although somewhat popular, there are still a few factors that limit this contactless solution from really gaining traction in the industrial environment, and the two main ones are directly related to the proximity of the user to the device. One is simple physics, the other is Computer Vision Syndrome (CVS).

Physics and Reaction Time

One aspect of the laws of inertia is the tendency of objects to keep moving in a straight line at a constant speed when no forces act upon them. An operator on a factory floor working with an interactive field might have a difficult time stopping his gloved finger less an inch from the surface, and will, more times than not, touch the display anyway.

Suboptimal Visual Working Conditions

Excessive glare from a screen or monitor increases visual demands on the operator and can lead to visual fatigue and an unnecessary high mental load. This condition is especially true in factories and workshops where OSHA workplace and lighting requirements mandate 750 Lux, as contrasted with offices which average 500 Lux. OSHA attributes eye strain, headaches and fatigue, and symptoms such as difficulty focusing and blurred or disturbed vision on poor lighting to glare from a digital screen. Studies also find that visual demands were increased in conditions where contrast glare was present, as well as frequent changes of focusing distances, and low contrast between background and characters in computer screens. Immediate treatments such as anti-glare films can effectively reduce glare from the screen by 55%, but over time the film disintegrates and loses its effectiveness.

A Mid-air Solution

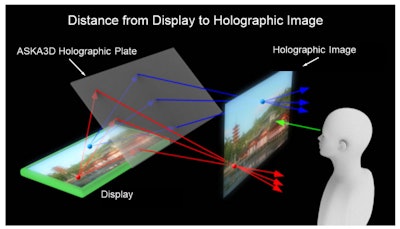

One viable solution is a mid-air contactless holographic HMI interface. While this technology also utilizes IR for HMI, it is the increased distance from the display that makes all the difference. Holographic Touch TM technology allows the user to interact 8-12 inches or more from a display or control panel, eliminating the propensity of workers piercing the IR light screen and touching the display's surface. In addition, since the user is interacting with a mid-air image and not a display, there's virtually no glare or reflection. (See Figure 1).

Figure 1: diagram showing the distance from the actual display to the holographic image.Holo Industries

Figure 1: diagram showing the distance from the actual display to the holographic image.Holo Industries

Holographic Touch preserves the benefits of contactless interaction, namely, operation wearing work gloves, germ-free interaction, less clean-up from greasy build-up on surfaces, and less damage to the display surface from over-enthusiastic interaction, without the negative effects of a contactless display.

Holographic Touch

In January 2020 — the same time as the COVID-19 pandemic swept through the US and the rest of the world — Holo Industries developed a contactless and germ-free way for people to interact with terminals, control panels and other devices. Holographic Touch is a transformative new technology that provides accurate and responsive mid-air interaction — without special lighting, glasses or headgear. In the past two years, this technology has transformed human-machine interaction and opened the world to new and exciting medical, hospitality, banking and industrial applications.

The Right Stuff

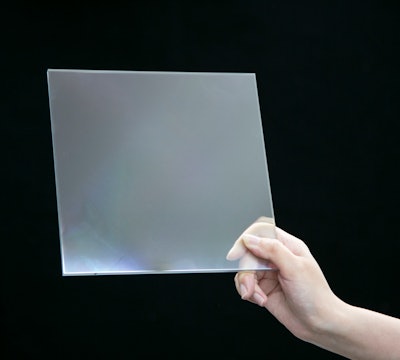

Thousands of hours of design and engineering has produced an interactive holographic product unrivaled by any other mid-air or “floating image” technology. Holographic Plates for our units are provided by ASKA3D, a Japanese manufacturer and division of Asukanet. (See Figure 2).

Figure 2: ASKA3D Holographic Plate.Holo Industries

Figure 2: ASKA3D Holographic Plate.Holo Industries

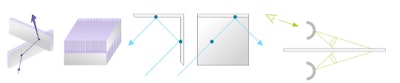

Each plate consists of methodically positioned vertical mirrors only hundreds of microns in size. (See figure 3). Two orthogonal specular surfaces reflect the light to project images.The first angle of incidence and the second angle of emergence have the same reflection angle, and the plate acts as a projection surface for displaying images in mid-air at a 1:1 ratio. ASKA3D technology collects light emitted by objects within a space, and then disperses the collected light from that space. Thus, users can see the image of an object in that space just like they see the light emitted by the actual object. Holo Industries is the distributor of ASKA3D Plates in the US and Europe and maintains the largest selection of holographic plates for monitors in the industry, from 50 mm (doorbells) to 2000 mm (machine interface displays and monitors).

Figure 3( L to R):ASKA3D Holographic Plate design, a Transmissive Dihedral Corner Reflector Array, and 1:1 Imaging technology.Holo Industries

Figure 3( L to R):ASKA3D Holographic Plate design, a Transmissive Dihedral Corner Reflector Array, and 1:1 Imaging technology.Holo Industries

Holo Industries’ mid-air interaction is achieved through a Neonode zForce IR sensor array that covers the surface of the holograph. Objects in the light path of the sensor cause intensity shifts in the received light, information which is then used to initiate tracking of the objects. By combining the measured value from multiple detectors, the position of the touch point is calculated in 50ms or less.

In addition to the Holographic plates and IR sensors every Holo integrated product contains:

- Patented coatings provide superior imaging.

- The highest NIT-value displays, guaranteeing a clear, precise holographic image, even in the brightest sunlight or artificial light

- Special optics and filters to reduce “Ghosting” for a clearer, crisper, image.

Conclusion

For germ-free interaction in factories and control rooms, contactless monitors and displays using IR as the HMI offer a positive alternative to touch screens. When IR is used in conjunction with Holographic Touch, false-touch and the suboptimal visual working conditions are eliminated, and the operator is free to experience the full benefits of contactless interaction.

About the Author:

Glenn ImObersteg is the CEO and co-founder of Holo Industries LLC. His industry background includes three decades of providing ecosystems and partner programs to Intel, Microsoft, Siemens, Infineon, ARM, Motorola, Freescale and other industry leaders in the embedded and microcontroller fields. As President of Convergence Promotions, he also owned IQ Magazine and ARM Developer’s Conference and founded Embedded Developer and Power Developer, joint ventures of Hearst Corporation and Arrow Electronics.