Dust. Dirt. Environmental extremes. Abrasive materials. Material handling conveyors face some of the toughest conditions imaginable. For the last 15 years, Atlas Equipment Services of Mayfield, KY has manufactured and serviced conveyors that are used in the mining and aggregates industries and to offload grain from riverboats. Their duty cycle varies, depending upon the application, but some of them run up to 24 hours a day, seven days a week. Unplanned downtime isn’t an option.

“For most of our customers, downtime is very expensive, because taking a conveyor out of service idles other parts of their production processes,” explains Shawn Hoover, owner of Atlas Equipment Services. “At one facility that uses our equipment, their downtime cost is in excess of $20,000 per hour!”

The Problem

In the past, Hoover built and sold conveyors with bearings that were pre-lubricated at the factory. Thereafter, his customers used manual lubrication to keep them in good operating condition. But that approach had a number of shortcomings.

“These conveyors are elevated, which means the bearings are often hard to reach. Many are inaccessible without an aerial lift,” he points out. As a result, they often weren’t lubricated as regularly as they should be.

In addition, maintenance personnel often didn’t clean off the grease fitting before lubricating the bearings. As a result, moisture and dust would get driven into the bearings during the lubrication process.

Why is this a problem? “A lot of rock dust is very abrasive,” Hoover points out. As a result, his customers’ less than rigorous manual lubrication practices tended to shorten bearing life.

The Solution

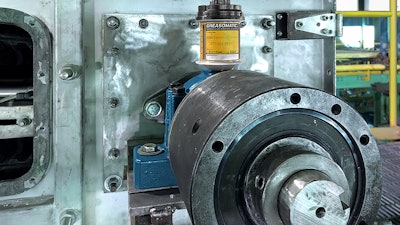

Hoover’s solution was to specify GREASOMATIC automatic lubricators supplied by Power Lube Industrial. These rugged, self-contained, programmable lubricators deliver a predictable amount of lubricant over a pre-defined period of time.

The GREASOMATIC automatic lubricator is powered by a simple chemical reaction. Upon activation, a combination of the patented adjustable galvanic element and electrolyte creates a steady release of internal gas. This powers a piston, which discharges the grease or oil of your choice. A translucent window in the body enables maintenance personnel to easily monitor the lubricant level and eliminates potential waste.

The GREASOMATIC also has a unique blocked-line indicator. This integrated pressure release vent provides visual evidence of blocked lubricant flow to the bearing.

With no batteries, electronics or wiring necessary, this simple and affordable lubricator can be easily programmed with the turn of a dial. It delivers 120cc of lubricant in a controlled, continuous flow over a pre-selected period. It offers seven settings, which enable you to program it for operation from one to 12 months, depending upon your need and the conveyor’s operating temperature.

In addition, GREASOMATIC lubricators can be mounted up to six feet from the lubrication point using flexible nylon tubing. This enables conveyor maintenance personnel to place them in optimal locations for easy and safe access.

Because of their simple “set it and forget it” design and reliability, Hoover says the GREASOMATIC lubricators have paid for themselves fairly quickly.

“The GREASOMATIC lubricators take the guesswork out of lubrication for our customers,” Hoover concludes. “They’re simple and foolproof.”

Greasomatics help mitigate bearing failure and expensive downtime on mission critical Atlas mining and aggregate conveyors at a bustling crushed-stone quarry.

Greasomatics help mitigate bearing failure and expensive downtime on mission critical Atlas mining and aggregate conveyors at a bustling crushed-stone quarry.