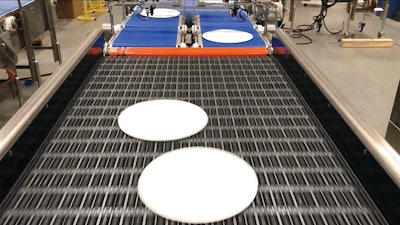

Multi-Conveyor (Winneconne, WI) recently built this metered servo merge conveyor as part of a larger system to transport packaged food. The metering conveyor feeds a series of servo belt conveyors to gap two lanes of product into a single lane flow using DARB technology.

A series of photo-sensors were strategically placed to sense product for the precise gapping needed to create a seamless high-speed merge without collision. We’ve slowed this video down slightly so you can witness the demo product pause (or gap) as needed before continuing to the single file merge.

The product transfers from a friction top chain metering conveyor to the high-friction top belt servo gapping conveyors, then roller transition merge through the final DARB belt merge. Products run simultaneously on two lanes, doubling the parts per minute (PPM) when merged, while moving at extremely high-level line speeds.

Standalone electrical controls included Nemo 4X stainless steel enclosures, VFD’s, servo drives, PLC, LED beacons and horns; and safety disconnects.