Drones That Can See in the Dark

Drones are being used more than ever before. They're being used to find pollutants at ammunition plants, battle fires, and just last week, we covered how they were being fired out of canisters for military missions.

To be able to carry out these missions, drones need to know their precise position at all times. Commercial drones typically use GPS, but that only works outside. When drones are operating indoors, they use conventional cameras, but if there isn't enough light, the computer vision receives blurred, unusable images. This has caused some drones to make some expensive additions, like adding laser scanners.

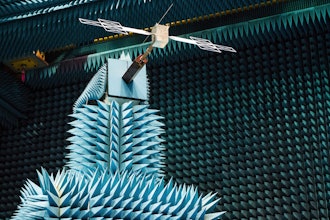

Researchers from the University of Zurich and the Swiss research consortium NCCR Robotics are using an eye-inspired camera that enables drones to fly in various conditions. The camera doesn't blur in high-speed conditions and it can even see in much darker conditions. The cameras don't actually need to capture full light on the bio-inspired retina, because they only report changes in brightness for each pixel, which produces sharp vision.

The researchers have also developed new software that can process the output from these cameras, so we could see drones indoors, and even when it's dark.

Airbus Installs First 3D-Printed Titanium Part

This week, Airbus installed the first 3D-printed titanium part on a commercial aircraft, the A350 XWB. The component was a bracket.

While 3D-printed parts have been used on several components found inside of the cabin, this milestone is significant because it is the first time a company is equipping airframes with metal parts that were created using additive manufacturing, specifically laser powder bed and electron beam processes.

The brackets were made by Arconic, an advanced manufacturing company that printed the parts for the widebody aircraft at its facility in Austin, Texas.

In April, Boeing said that it was going to start using 3D-printed titanium parts on its 787 Dreamliner. Made by Norsk Titanium, the parts could save Boeing up to $3 million on each jet. No word on what Airbus is saving on the A350 XWB.

Several 3D-printed parts are already used on Airbus test aircraft, but these are the first to be used on a production commercial aircraft. Arconic believes that while only a few components are 3D printed now, we could one day be flying in aircraft that are entirely 3D printed.

Laser Prototype Rips Holes in UAVs

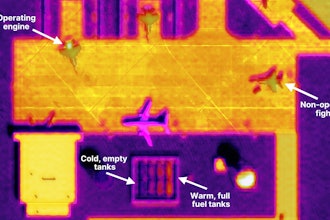

In August, Lockheed Martin took its prototype laser weapon out to White Sands Missile Range in New Mexico, to see if it could bring down unmanned aerial vehicles (UAVs) or drones that posed a threat.

In March, we learned that ATHENA had become twice as powerful, and now we have a chance to see it in action as the 30-kilowatt laser weapon system brought down five-out-of-five UAVs in a flawless victory.

In the video, you can see the Outlaw UAVs catch fire and be brought down with ATHENA's advanced beam control technology and fiber laser.

According to the official press release, the system officially "defeated airborne targets in flight by causing loss of control and structural failure." I suppose that is a little more elegant than "our laser ripped a hole in its tail."

This is Engineering By Design with David Mantey.