Polymer Made from Waste Cooking Oil Could Cure PFAS Pollution

PFAS, or per- and polyfluorinated alkyl substances (PFAS) are a problem. Also called "forever chemicals" PFAS are commonly used in non-stick coatings, lubricants and fire-fighting foams, but they are turning up everywhere.

The chemical has been linked to everything from cancer, increased cholesterol and pregnancies problems.

They have seeped into water systems across the nation and just this week, the FDA announced that it found "substantial levels" of PFAs in food; it was in everything from grocery store meats and seafood to an off-the-shelf chocolate cake. It's even in my wells.

So what are we doing about it? Not much. Some states have started suing manufacturers, but the nation seems crippled by the cleanup cost, which is estimated in the tens of billions of dollars.

However, researchers from the Flinders University Institute for NanoScale Science and Technology in Adelaide, Australia have created a safe, environmentally friendly and low cost way to remove PFAS from water -- it turns out that Australia has quite the PFAS problem too.

The researchers made an absorbent polymer from waste cooking oil and sulfur combined with powdered activated carbon (PAC).

PAC is a low cost sorbent used to remove micropollutants from water. However, is creates a hazardous dust that is flammable and a respiration hazard. It can also cake, which blocks filters and membranes. The sulfur polymer support solves these problems.

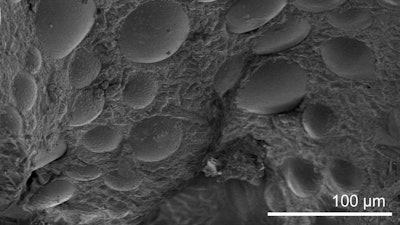

Magnified view of the Powdered Activated Carbon polymer which bonds with water-borne PFAS, enabling it's removal from the environment.Flinders University

Magnified view of the Powdered Activated Carbon polymer which bonds with water-borne PFAS, enabling it's removal from the environment.Flinders University

In initial tests, the polymer-carbon blend reduced the PFAS in a waters from 150 parts per trillion (ppt) to less than 23 parts per trillion (ppt), well below the 70 ppt limit set by the EPA and other health organizations.

Flinders University PhD candidate Nicholas Lundquist (left) and Dr Justin Chalker (right) with a field sample of PFAS contaminated water.Flinders University

Flinders University PhD candidate Nicholas Lundquist (left) and Dr Justin Chalker (right) with a field sample of PFAS contaminated water.Flinders University

The research was recently published in ACS Sustainable Chemistry & Engineering.

Next, the team plans to test the blend on a commercial scale to prove that it is capable of purifying thousands of gallons of water. They are also looking into ways to recycle the material and destroy the PFAS.

Why You Should Keep That Extra Toe

A team of researchers believes that the birth defect that leads to extra fingers and toes could provide a blueprint for a way to control robotic limbs.

The condition is known as polydactyly and it impacts one in every 500 babies.

The extra digits are typically removed after birth, but the researchers found a few patients who kept their sixth finger and are studying how their brains adapted to the extra workload.

The idea is to add robotic limbs and fingers to expand our natural abilities, like having a surgeon that controls a third (and robotic) arm.

The international team, made up of researchers from the University of Freiburg in Germany, Imperial College London, and the Université de Lausanne and EPFL in Switzerland, not only provided information for possible advancements in robotics, but also made a case for people to keep their extra limbs, as long as they’re well-formed and functional.

The researchers asked the subjects to perform various tasks, such as tying shoelaces, typing on their phones, and playing video games while they monitored brain activity on an fMRI machine. They observed a set of control subjects with five fingers performing the same tasks.

The researchers found that the extra fingers had their own tendons, muscles, and nerves, as well as an extra corresponding region in the brain. The subjects also performed many of the tasks better than their five-fingered counterparts.

The work, which was published in Nature Communications, is early, but controlling an extra robotic limb as well as a polydactyl person is unlikely -- after all, they’ve been working with it since they were born. But with this new research, it’s not impossible.

Foam Armor Designed to Stop Armor-Piercing Bullets

Researchers from North Carolina State have created a new armor out of composite metal foam (CMF). During tests, the researchers fired a .50-caliber armor-piercing round 514 meters per second at the foam. It bounced off, didn't even leave an indentation on the back plate.

They ran the same test with the bullet traveling 801 meters per second. It left a mark, but it was only 8 mm deep.

The foam not only performed as well as traditional steel armor, but it’s more than 50% lighter. This means that military vehicle designers could drastically cut down overall weight without losing on safety.

CMF is a foam made up of hollow, metallic spheres embedded into a metallic matrix made of steel, titanium, aluminum or other metallic alloys. For the study, the researchers worked with steel-steel CMF, which means that the spheres and matrix were steel.

The armor included a ceramic faceplate, the CMF core and a thin, aluminum back plate.

Dr. Afsaneh Rabiei, a professor of mechanical and aerospace engineering at NC State, has spent years developing CMFs and investigating their unusual properties.

It might be the coolest job in the world. In March 2018, she blew up a high explosive incendiary (HEI) round next to the foam to see if it could stand up to the blast pressure and fragmentation at 5,000 feet per second. That's an anti-aircraft weapon and it worked.

The foam also shields from X-rays, gamma rays and neutron radiation.

According to Rabiei, the foam could soon be used for everything from space exploration to shipping nuclear waste.

This is Engineering By Design.