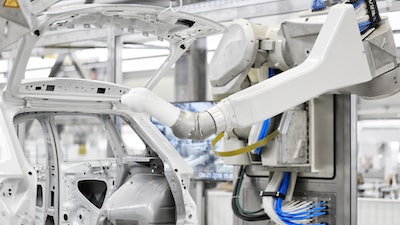

The new Ecopaint Robot generation from Dürr Systems (Southfield, MI) is designed with innovative functions for the automated painting process. Thanks to its greater kinematic freedom, the EcoRP E043i model with its seven-axis kinematic system enlarges the work zone and can eliminate the need for a linear displacement rail. This can significantly reduce investment and maintenance costs in the paint booth, says the company. Features include:

- Improved access to many areas, particularly in interior painting, and ability to avoid collisions with the vehicle.

- The EcoRCMP2 process and movement control system. This control platform combines numerous sensors and actuators belonging to the paint robot and the superordinate maintenance or control systems. An integrated interface makes the robot “cloud ready” and provides all relevant data to meet current and future demands in the Industry 4.0 environment.

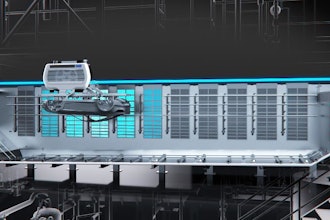

The six-axis variants are still available in the product range and, apart from the missing seventh axis, they are identical to the seven-axis robot and are used with or without displacement axis. The EcoRP E/L133i robots operate either on a top- or bottom-mounted rail. In addition to painting, they also serve as lid openers in interior painting. Paint robots of this new generation can be placed anywhere. For example, they can be installed on the floor, wall, ceiling or at an angle in the paint booth.

www.durrusa.com; 248-450-2000