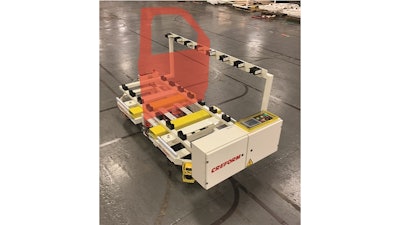

Creform (Greer, SC) has introduced a custom-designed bi-directional AGV, the CA-B50100 model, which holds body closure panels for an automotive body shop assembly operation. The 20-plus AGVs move welded panels from the body shop to the assembly line. They feature radio link to Creform’s vehicle traffic control system for efficient material flow via vehicle routing. The system replaces forklifts and provides production efficiencies of automation and safe handling.

The fabricated steel AGV base is constructed for strength and durability with fixtures designed to hold the various sized panels. Cushioned mounts hold the panels separate from one another to secure and minimize the risk of damage. The AGV runs two shifts per day on a route that features six stops where it sets for a period of time. The vehicle stops automatically and starts after a period of time unless manually started by attending associate.

The model is bi-directional with bolt-on drive units and provides great flexibility for movement along its approximate 2000 ft. embedded magnetic strip guidepath and can travel in both directions and when necessary, travel laterally or even rotate in place.

www.creform.com, 800-839-8823