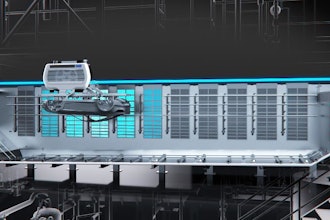

The Bowman L Series desktop instrument was engineered for OEMs and contract shops who need precise control over the thickness of plated deposits.

Bowman

Bowman (Schaumburg, IL), a U.S. manufacturer of XRF coating measurement instruments, has introduced its large component L Series XRF for parts measuring up to 22" X 24" X 13". The Bowman L Series desktop instrument was engineered for OEMs and contract shops who need precise control over the thickness of plated deposits, preventing the quality issues that result from under-plating, and the cost consequences of over-plating. Additional features include:

- The ability to determine the thickness of coatings within a broad range, from aluminum through uranium (13 through 92 on the periodic table).

- The ability to measure up to five coating layers simultaneously.

- A proprietary micro spot focus x-ray tube.

- A temperature-stabilized silicon PIN diode detector — element peaks eliminate the need for secondary filters.

- Minimal peak position drift assures stability over time and extends the interval between recalibrations.

- A 4-position multiple collimator assembly — collimator sizes and focal distances can be tailored to the application.

- A micro-focus video camera, synchronized with the x-ray optics, that pinpoints the target.

- The ability to accommodate recessed areas and unusual part geometries.

- Xralizer software to quantify coating thickness from the detected photons.

For more information, call 847-781-3523, or visit www.bowmanxrf.com.